Work holding is a critical aspect of CNC milling, ensuring your workpiece stays secure and precisely positioned throughout the machining process. Improper work holding can lead to ruined parts, damaged tools, or even accidents. Here’s a beginner-friendly guide to understanding work holding for CNC milling:

What is Work Holding?

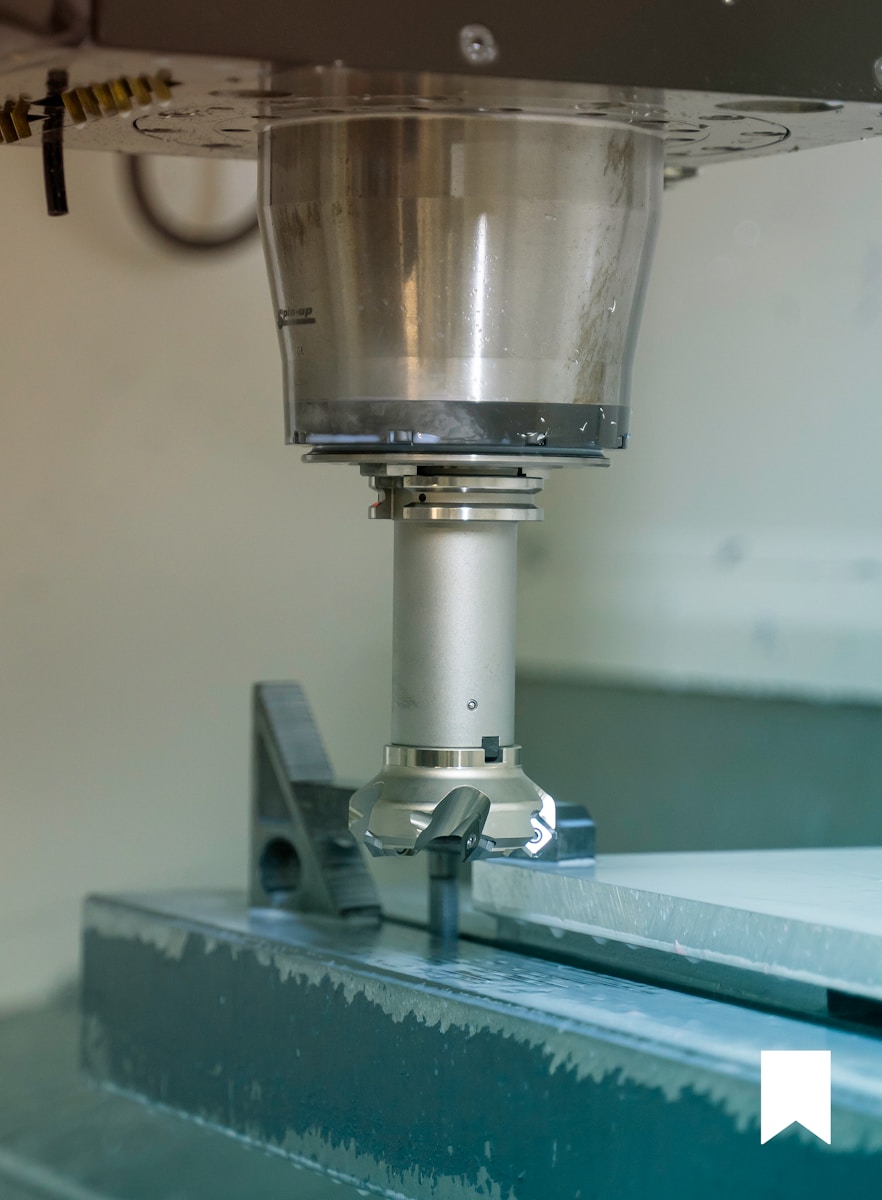

In CNC milling, work holding refers to the methods and devices used to secure the workpiece to the machine table, preventing movement or vibration during cutting. A stable workpiece is essential for achieving accurate dimensions and a smooth surface finish.

Common Work Holding Techniques:

-

Vises: Vises are versatile work holding devices ideal for holding rectangular or square workpieces. They clamp the workpiece firmly between two jaws, providing a secure hold.

-

Clamps: Clamps come in various shapes and sizes, offering flexibility in securing irregularly shaped workpieces. They typically use a screw mechanism to apply pressure and hold the workpiece against a fixed surface.

-

Fixtures: Fixtures are custom-designed work holding devices tailored to hold specific workpieces. They often incorporate multiple clamps, locators, and other features to ensure precise positioning and repeatability.

-

Vacuum Chucks: Vacuum chucks use suction to hold flat workpieces. They are particularly useful for delicate materials or parts with thin walls, as they distribute the clamping force evenly.

Choosing the Right Work Holding Method:

Selecting the appropriate work holding method depends on factors like:

- Workpiece Material: Different materials have varying hardness and clamping requirements.

- Workpiece Geometry: The shape and size of the workpiece dictate the type of work holding suitable.

- Cutting Forces: Heavier cuts require more robust work holding to withstand the increased forces.

- Accuracy Requirements: High-precision machining demands secure and repeatable work holding.

Pro Tips:

- Always use adequate clamping force to prevent workpiece movement, but avoid excessive pressure that could damage the part.

- Consider using parallels or soft jaws to protect delicate workpiece surfaces from marring.

Tags: CNC, CNC Milling, Work Holding, Beginners Guide, DIY